Presentation of the company

Since its foundation in 1982, Hinteregger has been active in the field of mould and model making. The initially small company originally specialised in the construction and development of casting tools and models. Even back then, the technical equipment, commitment and expertise guaranteed first-class performance. The still owner-managed family business has grown steadily and has always been able to withstand the changes in the industry and develop further.

A strong will to innovate has enabled Hinteregger GmbH to successfully meet new challenges and expand its portfolio. Today, Hinteregger GmbH is a reliable partner for the automotive, aerospace, medical and research technology industries.

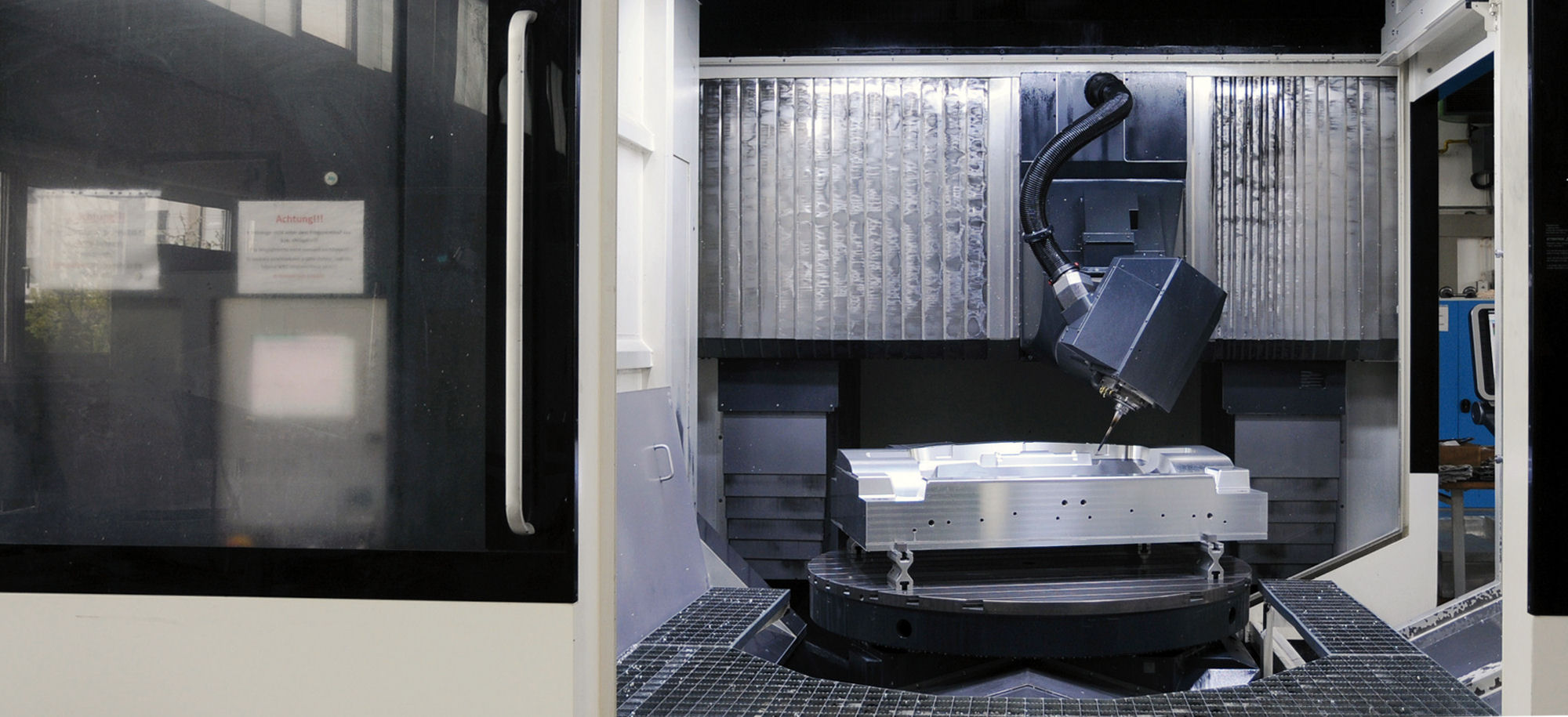

We now employ more than 50 people at our site in Bruckmühl. The continuous expansion of our machinery and investment in modern technologies enables us to continue to deliver products of the highest quality.

Unsere Firmenphilosophie

Our company philosophy

“Production at the highest level” is our guiding principle, which we live by every day. We stand for the highest quality, innovation and development. These maxims determine all our actions in order to fulfil the requirements and wishes of our customers.

We focus on a reliable, fair, sustainable and transparent relationship with our customers, suppliers and employees. A personal and constructive partnership is very important to us.

We are committed to respecting human rights, fair labour practices, appropriate treatment of employees and suppliers, responsible treatment of our environment and against discrimination and exclusion.

Unsere Firmenphilosophie

Know How

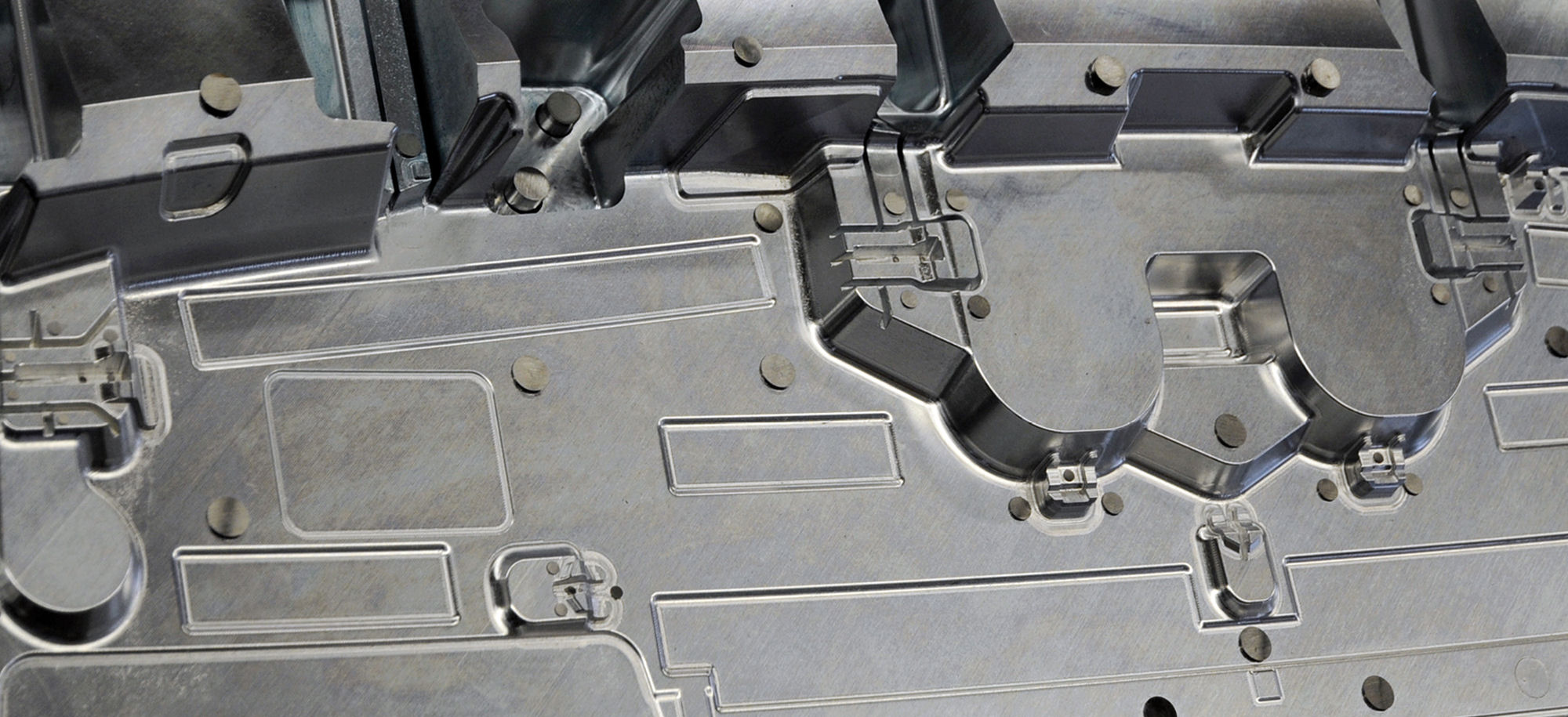

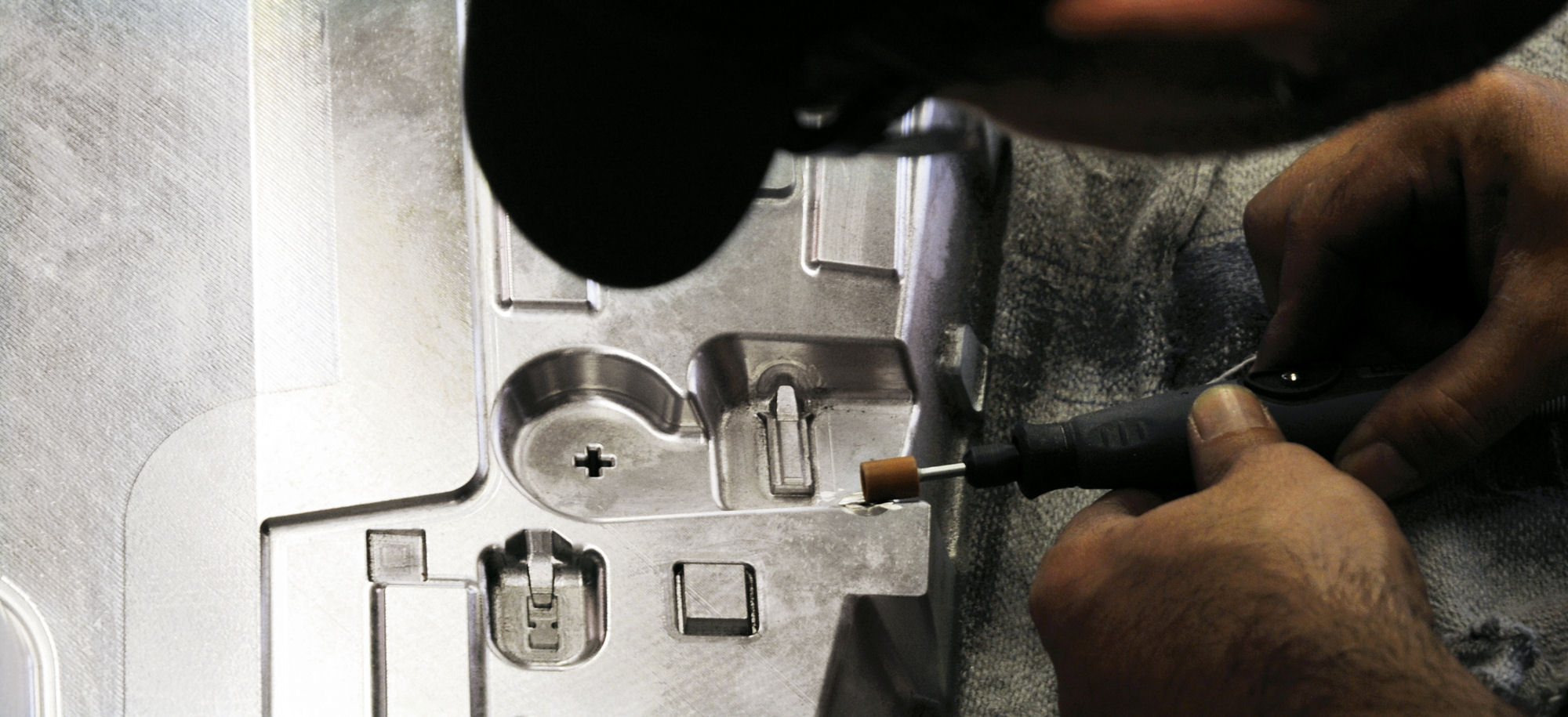

For over 40 years, Hinteregger GmbH has been developing customised and complete technical solutions on behalf of customers. From the initial concept design to the calculation, the development of the first prototypes – right through to series production. Our range of services includes injection moulding tools for prototypes and small series, jig and fixture construction, as well as the manufacture of complex milled parts.

Are you planning a project?

Whether prototypes or series parts – with us you get everything from a single source. From the consultation and development of your components, to the design and manufacture of the equipment, as well as the production of your components, our entire expertise is at your disposal.

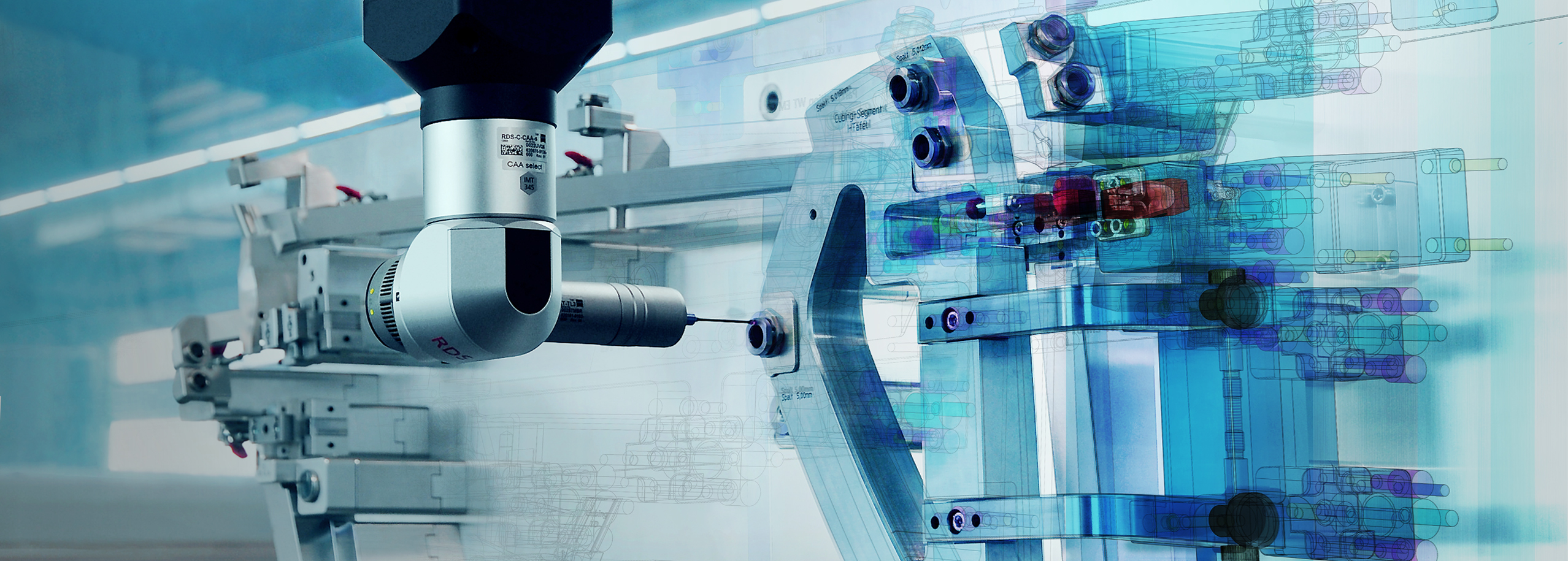

Thanks to our excellently equipped quality assurance department and decades of experience in the construction of test equipment, we can also offer you support with the dimensional testing of your components.

We attach particular importance to professional customer service and target-orientated project management. Do you have any questions? Contact us – a dedicated and highly qualified team awaits you and your ideas.

Unsere Firmenphilosophie

Responsibility / Environmental management

Sustainability is important to us.

Through our actions, we want to make a contribution to a sustainable future. Acting sustainably means taking responsibility. Through our activities and decisions, we can make a positive contribution to our environment, our climate and future generations. Years ago, we recognised sustainable energy generation as an important building block for us. Photovoltaic systems have been installed on our entire production halls. This means that we can already generate part of our energy requirements from our own production.

All of our moulds are fed directly into the recycling cycle after they are worn out, enabling us to reuse this material for new projects. We work closely with our suppliers to achieve this. This gives us the opportunity to cover a large part of our raw material requirements with recycled material and thus make a positive contribution to a more sustainable product.

We have set ourselves the goal of fulfilling our social, economic and ecological responsibility by using raw materials and energy sparingly, employing efficient production processes and using modern production machinery.

Unsere Firmenphilosophie

Certification

Quality management

Made in Germany” has always been a guarantee of good quality. Even today, no German company can afford to deliver poor quality in a highly competitive global market. However, the quality requirements, which often reach the limits of what is technically feasible, require more than the utmost care. It requires a closed quality management system (QMS).

Certification

We, Hinteregger GmbH, have also adapted to the increasing complexity. In 2008, in co-operation with All-Cert GmbH – a specialist in the field of certification – we successfully completed DIN ISO 9001 certification. DIN ISO 9001 generally covers the design, development, production, assembly and maintenance sectors. We have introduced the quality management system for our field of activity, mould and tool making and mechanical processing, and will also successfully master future audits.

Zertifizierung